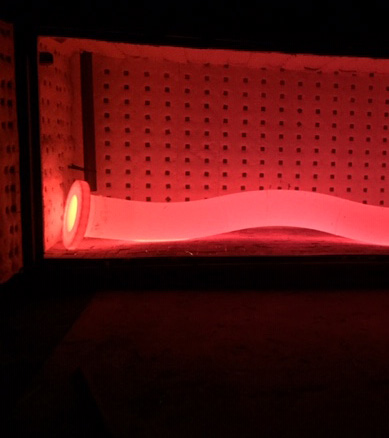

Normalising and Annealing Heat Treatments are undertaken to improve the mechanical properties of metals.

These processes may be used to improve tensile strength, hardness and ductability. In some cases treatment will be used as a precursor to surface hardening. Normalising is often used to improve the “machinability” of metal.

Normalising, while offering an element of stress relief within the material, is generally undertaken at higher temperatures than stress relieving, with an aim to alter the structure of the material. For instance, when normalising mild steel the target temperature would be approximately 900ºC. This is generally 30ºC to 50ºC above the upper critical point.

Annealing ferrous metals requires controlled and slow cooling after heating.

National Heat has the experience, equipment and staff to offer effective solutions for your heat treatment needs. We can transport and construct a portable modular furnace anywhere in Australia, Papua New Guinea or the Pacific Region.

View Other Services